Cladify Systems

AirLayer™ Panel Technology adapted from the Aerospace Industry

Cladify panels are designed for extreme strength, low weight, and high rigidity. At their core is our AIRLAYER™ panel technology—which is based on a series of proprietary lamination techniques adapted from the aerospace industry. The technology includes a series of proprietary cell cores sandwiched between two continuous layers of solid sheathing. The cladding layer, situated on top of the core, is a 2 to 5mm (0.08-0.20”) veneer of natural or engineered material bonded with a special, fire-resistant adhesive (also adapted from the aerospace industry). This adhesive was chosen for its ability to withstand 300 MPH winds, very high sheering forces, tensile forces, and a wide range of temperature extremes… all without delaminating or losing any structural integrity.

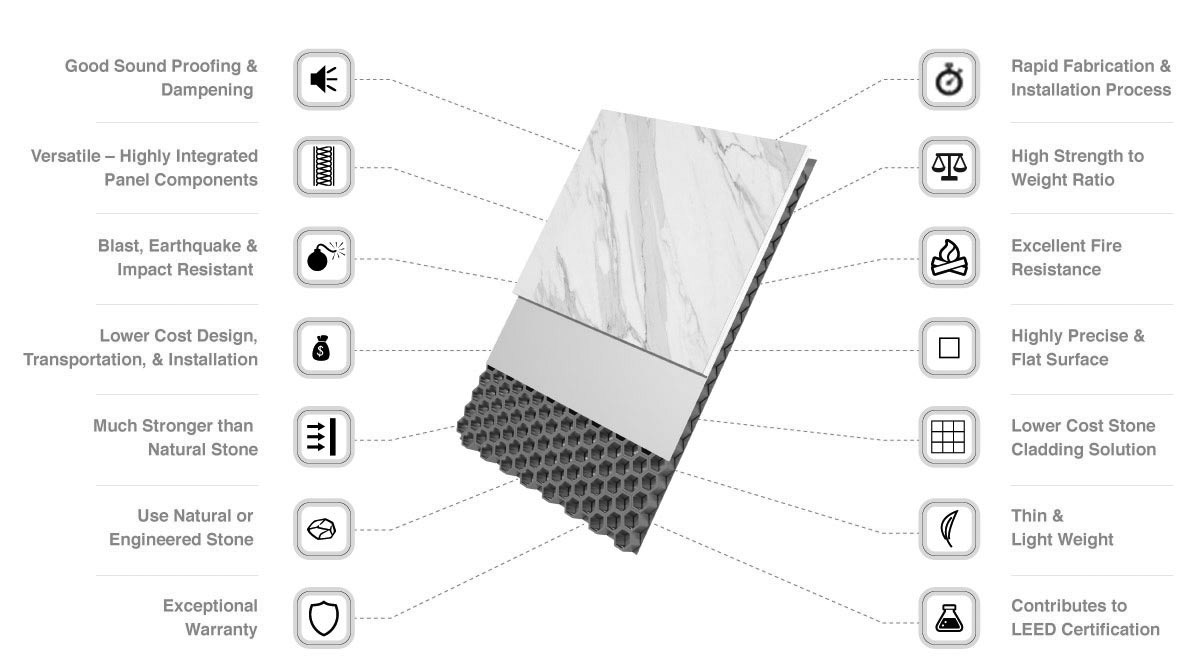

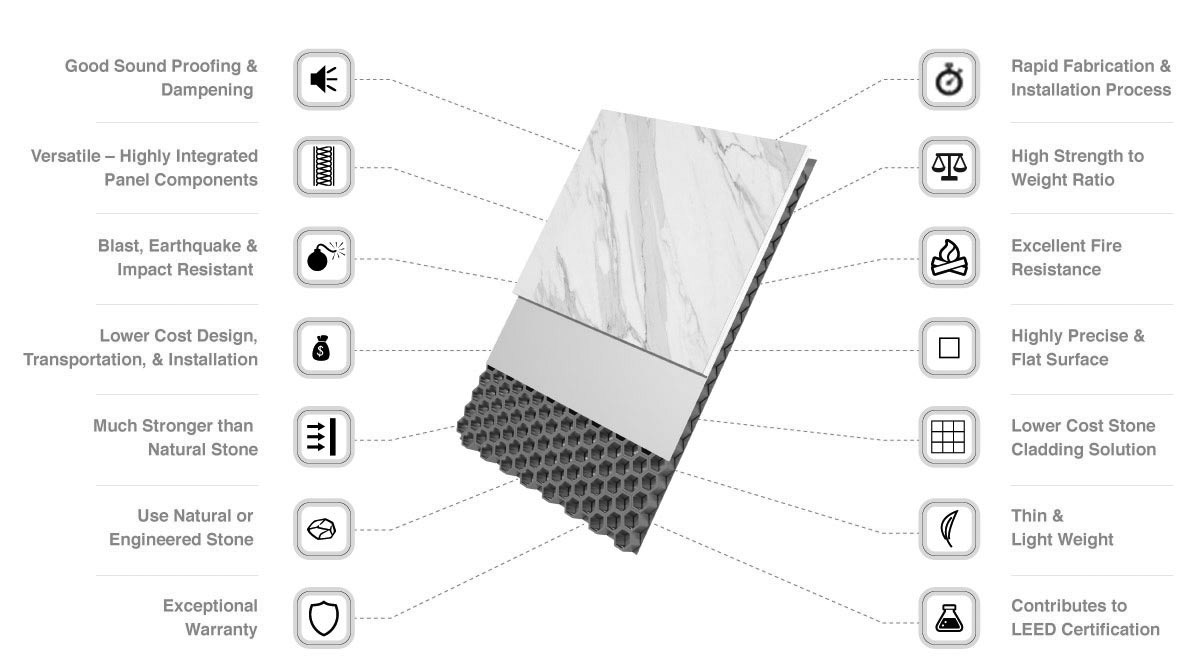

Key Benefits

Benefits

Our sustainable facades have numerous benefits over traditional cladding systems.

Our cladding is highly engineered and manufactured to exceedingly precise levels of quality and finishing.

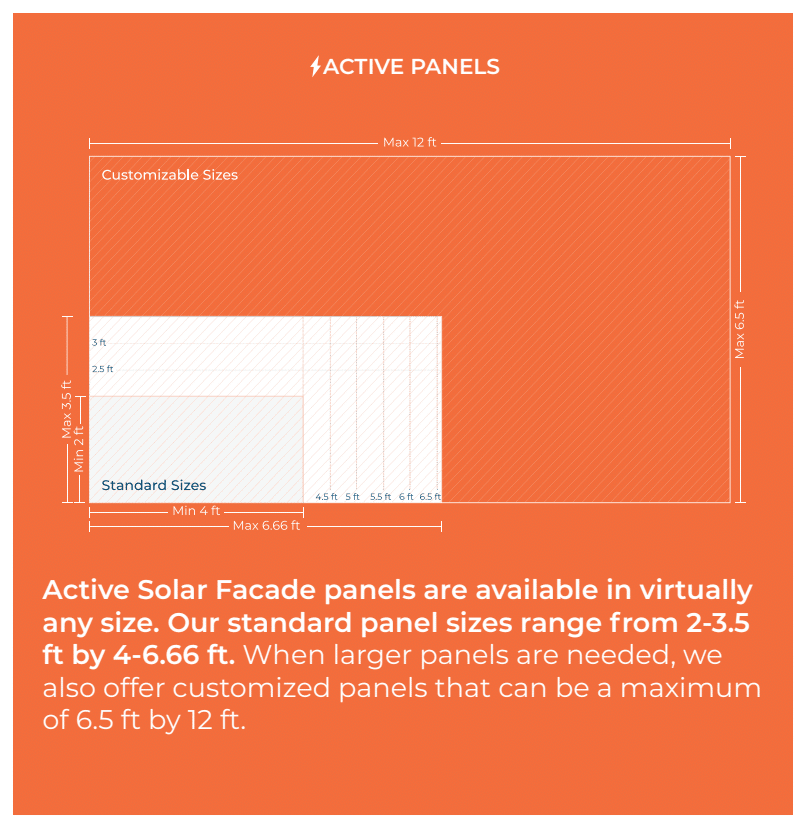

ACTIVE & NON-ACTIVE PANELS OPTIONS

We offer our sustainable facade solutions in two options: active solar cladding that can generate energy with integrated solar technology and non-active cladding with limitless facing material options.The option of energy-generating active facade products can allow any structure to become a micro powerplant without altering aesthetics or increasing costs.

INTERCHANGEABLE MATERIALS

The panels can be engineered with virtually any facing material in the world! From brick to stone, porcelain, glass, metal or even solar, our products can conform to any design need. The interchangeable facings allow for easy and seamless incorporation into any project and offer truly versatile solutions.

CUSTOM TEXTURES, SHAPES, & SIZES

Not only can our panels be made with almost any material available, but there are custom options to suit various textures, finishes, shapes, and sizes.

VERSATILE APPLICATIONS

Ideal for new, out-of-the-box design ideas because they can be fabricated into virtually any shape, size, or pattern required. Perfect for exterior or interior applications on any surface in new construction, renovations, and retrofits for any building type.

EXTREMELY STRONG

Our cladding panels have exceptional crush strength and stiffness, constant crush strength, structural integrity, and fatigue resistance. Thicker honeycomb cores will provide even greater strength and spans.

THIN & LIGHTWEIGHT

Up to 80% lighter than traditional stone, steel, wood, or common partitioning materials. They are typically only 1” thick, leaving more room for insulation and floor space. This also means greater ease-of-use and significantly lower costs for transportation, handling, and installation.

HIGHLY INTEGRATED PANEL COMPONENTS

A building envelope composed of both typical cladding and solar cladding is possible with Cladify and Mitrex panels, BENEFITS allowing for fully integrated energy generation. The various types of panels are engineered in such a way that they seamlessly integrate with one another for virtually any cladding application imagined.

RAPID FABRICATION

Our panels can be fabricated in a relatively short time frame at our fully automated facility. Panels can be constructed as work progresses and delivered on-site according to your schedule, ready to install. As a single-source supplier, the scheduling and production staff can help to keep client project schedules on track.

YEAR-ROUND INSTALLATION

The panels are fabricated under factory-controlled conditions, and they can be installed year-round. Harsh winter weather and rain will have minimal impact on the production and installation schedules.

RAPID INSTALLATION SPEED

With its high-strength and low-weight density of approximately 3.2 lbs/ft2, installers can quickly and easily install our panels. Lightweight panels allow smaller 14 crews to install and cover more area faster than with conventional materials. A faster erection will lessen the contractor’s risks and costs associated with weather and material damage during construction.

QUICKER & LOWER COST DESIGN

Our system takes less time to design than conventional brick, masonry, or traditional cladding systems. It offers designers and engineers pre-engineered strength capabilities and pre-designed anchoring systems. This eliminates the multiple variables of conventional cladding

materials that can slow down the design and engineering process.

LOW COST

The panels are much lower in cost when you compare the costs of purchase, transportation, handling, and installation of alternative cladding options.

HIGHLY PRECISE & FLAT SURFACE

Our panels can achieve highly flat surfaces, creating a seamless building envelope. Accurate and trouble-free installations allow us to achieve precise surfaces in any project.

EXCELLENT FIRE RESISTANCE

The aluminum honeycomb panels are highly fire-resistant compared to wood, PVC, insulation, drywall, and other sheathing materials. They are composed of non- combustible materials and are rated UBC Class 1 for fire and are self-extinguishing.

GOOD SOUND PROOFING & DAMPENING

The hollow, honeycomb core is highly absorbent to sound and can be used in numerous sound damping and soundproofing applications.

BLAST, EARTHQUAKE, & IMPACT RESISTANT

Our panels are remarkably impacted and crack-resistant because they flex without breaking. They can withstand 60 times more impact than a 1 3/4” solid granite panel when tested with a large missile impact test. That means that they are blast and earthquake-resistant when used as an exterior envelope.

IMPERVIOUS TO MOISTURE PENETRATION

The panels are impervious to moisture penetration which can cause mold or mildew.

APPLICATION SOLUTION CONSULTING

As architects, engineers, and experienced field technologists, we know how to specify and apply our products to solve real-world design and construction problems. Everything from complex design challenges to never-been-done-before design concepts to achieving demanding construction budgets are all within our reach. With more than 20+ years of application experience, we know how to develop creative and elegant solutions to meet your needs.

AN EXCEPTIONAL WARRANTY

Our panels are guaranteed not to delaminate for the life of the structure, provided that they are installed properly using certified installers. For our solar facades, the warranty ensures the hardware will last for 25 years and guarantees that after 25 years the minimum efficiency will be 80% of the original energy generation.

ENDLESS FABRICATION OPTIONS

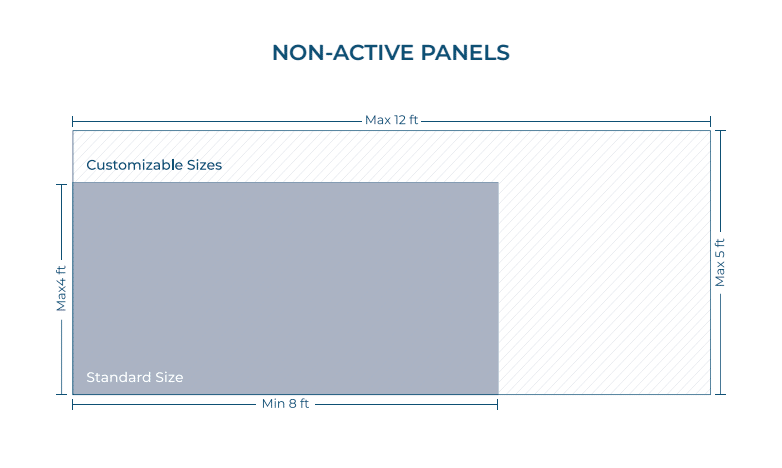

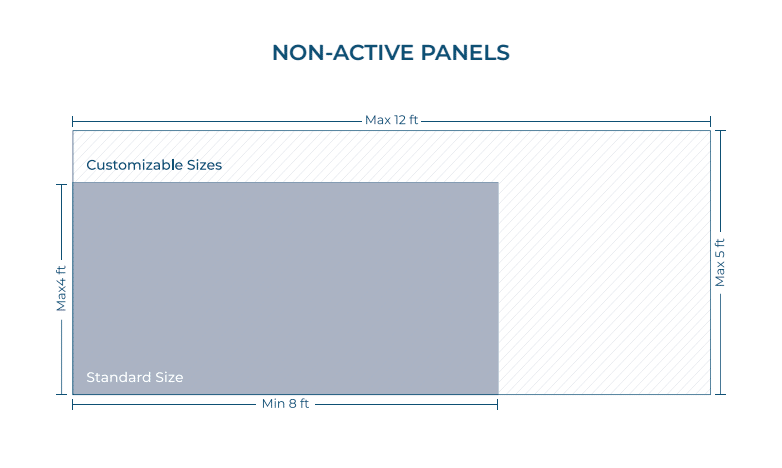

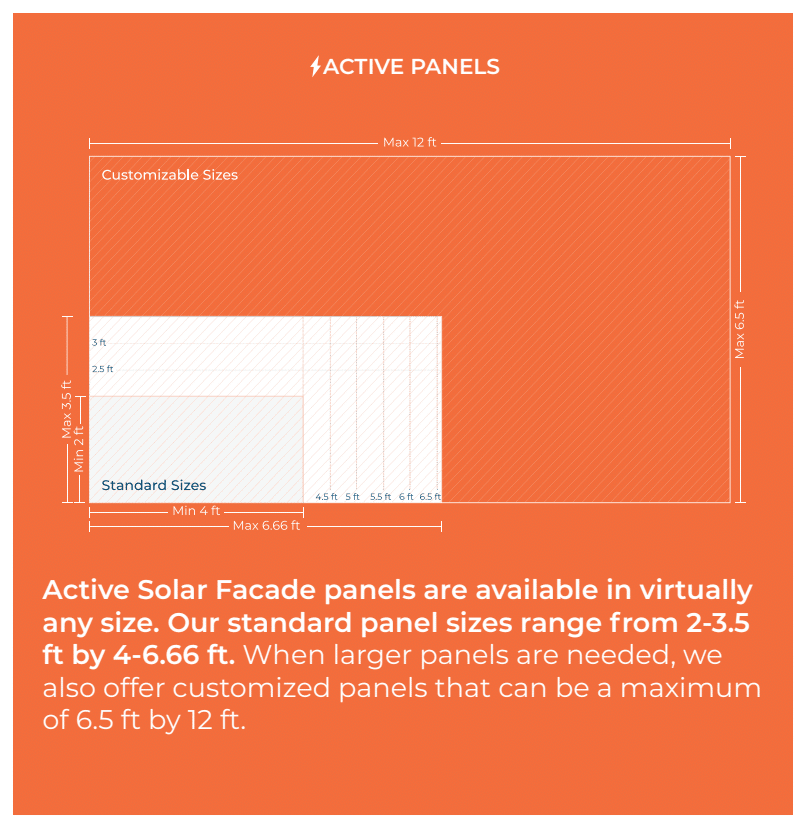

ADAPTABLE PANELS SIZES

Non-active standard sized panel is 4ft by 8ft, with a maximum of 5ft by 12ft.

We can also cut-to sizecustom square or rectangular shapes, cut-outsin panels, and other angular and curved shapes depending on your needs. In a nutshell, we can doalmost anything that you can conceive or require.

Our panels can be produced with curved or angular shapes, grooves, and in virtually any size. Our advanced manufacturing process ensures panels are completely customizable in terms of shapes, designs, and sizes within the maximum dimensions.

CUSTOMIZABLE ELEMENTS

Our panels can be provided in varying thicknesses of starting from 9/16 (14 mm) and weigh only 3.2 lbs/ft2 (15.6 kg /m²).

Our panels can be embedded with names, emblems, logos, signs, or other custom designs through CNC machines. This is perfect for exterior or interior retail and commercial applications.